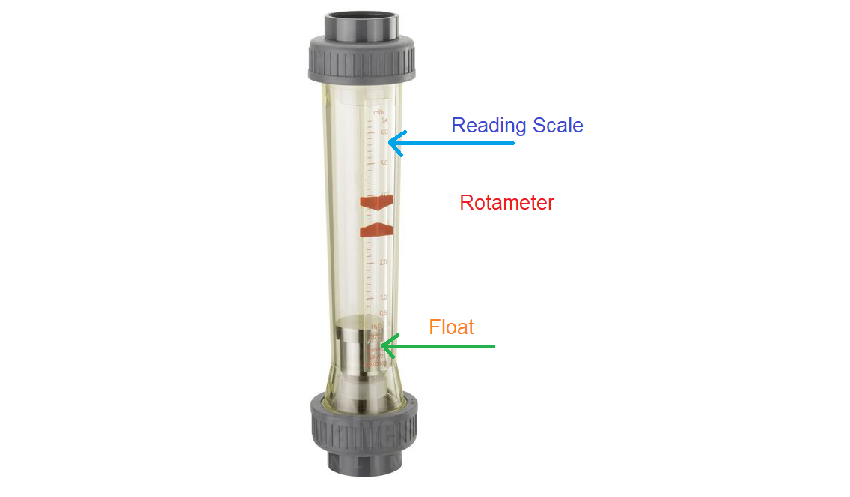

The variable area flowmeter is an instrument device used for measuring the flow of liquids and gases in pipelines. It is constructed in a vertical tube form through which the fluid (clean liquid or gas) flows from bottom to top. Its diameter also increases from bottom to top as shown in the fig. when the fluid passes through the tube, the float moves vertically upward in a tube. It may be noted that as the flow rate of the fluid is increased, thus float moves to a higher position until its resistance to the fluid flow is balanced by the floats buoyed weight in the fluid, a value which is constant and independent of the flowrate. It can be stated that the position of the float is a measure of the flowrate. Rotameter is an example of a variable are flowmeter and is used for measuring the flow of low viscous fluid at high velocity. Rotameter is widely used as a variable area flowmeter because of low cost, easy installation, low maintenance, low pressure drop, relativity wide range ability and linear output. When the fluid enters the rotameter from the bottom, it raises the position of the float in the tapered tube. At any instant of time float experiences two forces in the opposite direction:- 1) Drag force / buoyant force in upward direction. 2) Gravitational force in downward direction. As the float moves upward in the tapered tube, the fluid passing area increases, Which leads to decrease in differential pressure. The upward motion of the floats end when the dead load is dynamically balanced by the differential pressure. The tapered tube is so designed that the vertical movement of the float becomes linearly proportional to the rate of flow and the scale is provided to note the reading of the float which actually gives the value of the flowrate. The working principle of rotameter is based on Bernoulli’s theorem.